Laser Cutting

Why choose Laser Cutting?

Accuracy

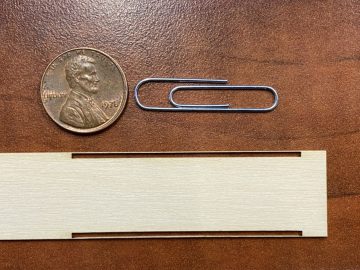

We house multiple CO2 lasers that are the most accurate in the world holding up to a tolerance of +/- 0.002" when cutting various materials.

Bed Size

Bigger the better and we have the largest laser cutting surface area in North America. We can cut sheet material up to 60" x 96" (1524 x 2438.4 mm) and roll sizes up to 70" (1778 mm) wide.

Edge Quality

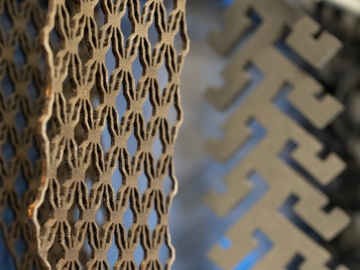

With some materials we can cut up to 1.0" (25.4 mm) in thickness. A laser cut edge is smooth and with most materials it doesn't require any deburring or polishing.

Nesting

The kerf of the beam is so small that when nesting multiple pieces, the spacing in between can be as thin as 0.1" (2.54 mm). It creates less waste and can reduce material costs dramatically.

Common Laser Cutting Materials

ABS

Acetal

Acrylic

Adhesives

Cardboard

Chipboard

Foam

Film

Hardboard

Laminate

Leather

MDF

Paper

PEEK

PET

PETG

Polypropylene

PTFE

Romark®

Rubber

Textiles

VELCRO®

Veneer

Wood